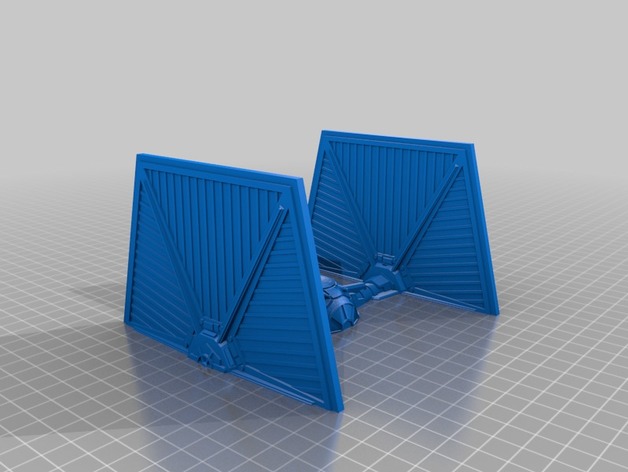

12 hours ago, thestag said:Awesome! I'm going to see about printing that this week. I might push the envelope by printing at .1mm on my Prusa Mini. I'll post pics if I'm able to get it done. Thanks!

Good

Let me know if assembly is fine, as there is always room for improvement